Replace a chainsaw chain when the cutting teeth are broken, cracked, or worn down to the wear line. Replace the chain if the saw cuts crooked, smokes, or requires excessive force even after proper sharpening and tensioning. These symptoms indicate excessive wear or damage that reduces cutting efficiency and creates safety risks.

When to Replace a Chainsaw Chain

Even well-maintained chainsaws eventually need chain replacement. First and foremost, knowing the right time to replace your chainsaw chain prevents accidents and ensures optimal cutting performance.

Wear markers and what they mean

Every tooth on quality chainsaw chains features specific wear markers that serve as visual indicators. These marks (typically shown in red on STIHL chains) appear on multiple parts of the tooth. Once you’ve filed the chain down to these markers, replacement becomes necessary. Filing past these indicators significantly reduces cutting performance and increases the risk of tooth breakage.

How to tell when a chainsaw chain is worn out

A chainsaw chain that needs replacement often exhibits several telltale signs. If your chainsaw produces fine dust instead of proper wood chips, the chain is likely worn out. Similarly, if the saw requires excessive pressure to cut through wood or starts making crooked cuts, it’s time for a new chain.

Frequent users can expect their chainsaw chain to last approximately five years with proper maintenance. Nevertheless, excessive chain vibration, difficulty maintaining stability during operation, or a smoking chainsaw despite proper lubrication all indicate the chain has reached the end of its useful life.

Damaged or missing teeth

Hitting unexpected objects like nails, rocks, or metal within trees can cause significant damage to chainsaw teeth. As a result, if you notice:

- Missing teeth on the chain

- Broken or cracked teeth

- Severely chipped cutting teeth

- Uneven teeth beyond practical correction

Replacement is the only safe option. Continuing to use a chain with these defects creates serious safety hazards and severely compromises cutting efficiency.

Chain no longer holds sharpness

When your chain requires increasingly frequent sharpening yet dulls quickly after minimal use, it’s a clear sign the chain needs replacement. Of course, chains can be resharpened numerous times throughout their lifespan. However, once the cutting tooth has been worn down from cutting or sharpening to the point where it’s almost as wide as the chain links, replacement becomes necessary.

Additionally, if the chain has stretched to the point where it cannot be properly tensioned anymore, this indicates the chain has reached the end of its useful life.

When to Replace the Chain Sprocket

The sprocket, though small, plays a crucial role in your chainsaw’s operation by transferring power from the engine to the cutting chain. Located behind the sprocket cover, this component experiences significant wear with regular use.

Understanding sprocket wear depth

Measuring sprocket wear requires careful inspection. The chain sprocket must be replaced once wear marks reach approximately 0.5mm in depth. This measurement serves as the definitive wear limit for most chainsaws. Professional users often check sprocket condition using a control gage, which works on both rim and spur sprockets found on petrol or cordless chainsaws.

A practical rule of thumb many professionals follow: replace your chainsaw’s drive sprocket after wearing out two chains. Furthermore, if you rotate between multiple chains rather than continuously resharpening a single chain, consider replacing the sprocket whenever you replace the guide bar.

To properly inspect your sprocket, remove the side cover and bar, then examine the sprocket teeth carefully. Healthy teeth should be smooth, consistent, and symmetrical without warping. Conversely, worn sprockets typically show:

- Deep grooves or sharp ridges where chain driver links make contact

- Chipped, uneven, or pointed teeth

- Excessive wear channels exceeding wear indicators

How a worn sprocket affects chain performance

A seriously worn sprocket creates a cascade of problems throughout your cutting system. Essentially, as sprockets deteriorate, they cause chainsaw chains and guide bars to wear at an accelerated rate while simultaneously reducing cutting performance.

This happens because worn sprockets alter the pitch (tooth spacing), causing power loss and improper chain engagement. Consequently, you’ll notice several performance issues, including difficulty tensioning the chain, more frequent chain derailments, gradual loss of torque, and increased vibration while cutting.

Perhaps most telling, when you manually rotate the chain on a stopped saw with a worn sprocket, you’ll feel binding, clunking, or slipping rather than smooth movement. Importantly, these symptoms often appear before catastrophic failure occurs.

Since the sprocket is relatively inexpensive compared to fixing damage caused by worn components, prioritize replacement when these warning signs appear. This preventive approach maintains cutting efficiency and prevents unnecessary strain on your chainsaw’s other components.

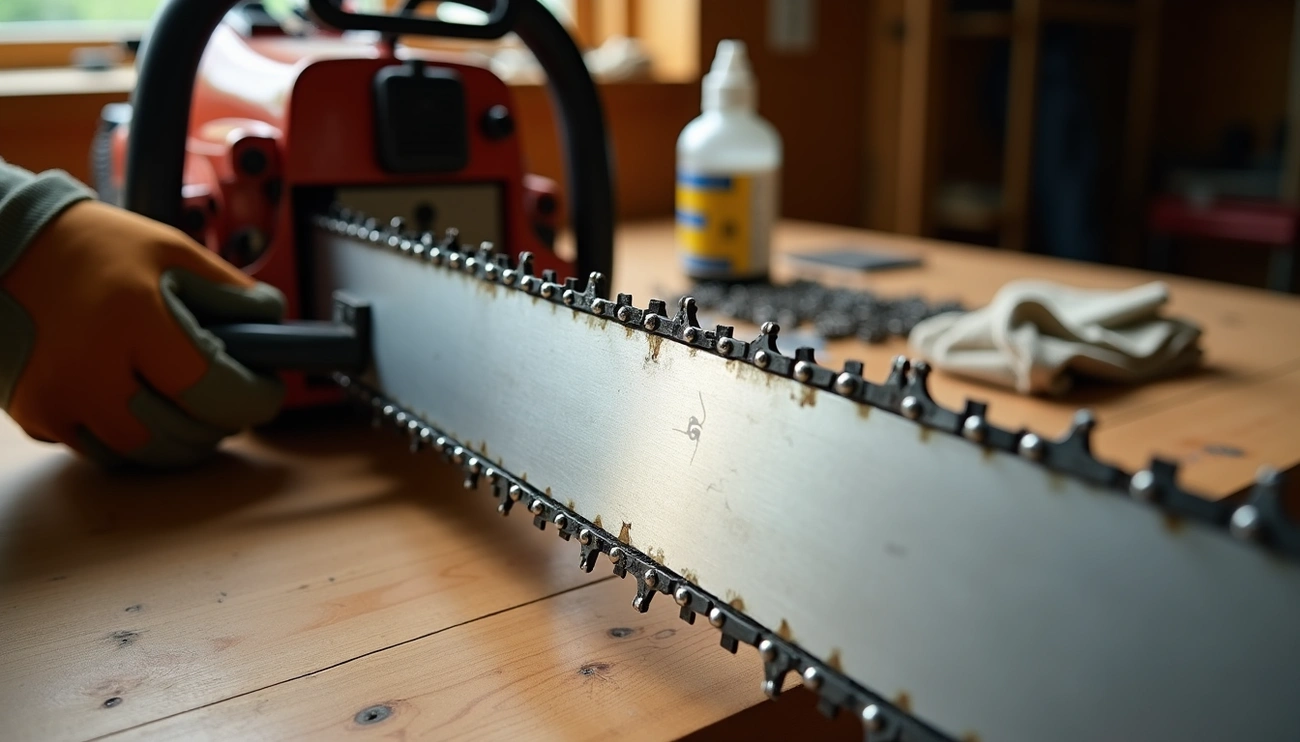

When to Replace the Guide Bar

Your chainsaw’s guide bar supports and directs the cutting chain throughout its high-speed journey. Recognizing when this crucial component needs replacement prevents accidents and maintains cutting efficiency.

Rail wear and groove depth issues

Guide bar rails gradually wear down with use, reducing the groove depth where drive links travel. If the groove becomes too shallow, the drive links scrape the bottom, creating friction and affecting chain movement. First thing to remember, check groove depth using the tip of a depth gage tool. According to experts, when groove depth measures less than manufacturer minimums (typically below 5/16″ minimum), replacement becomes necessary. Moreover, if the bar rails aren’t flat and square, the chain will wobble excessively side-to-side.

Guide bar damage: bent, chipped, or pinched

Inspect your guide bar regularly for these damage signs:

- Bent bar: Sight down the rails as if aiming a gun to spot bends

- Pinched rails: Creates “hot spots” causing permanent damage

- Chipping or metal loss: Particularly behind the bar nose

- Blue discoloration: Indicates overheating damage

Generally, minor damage like slight pinching can be repaired, yet severely bent or cracked bars should be replaced.

How long do guide bars typically last?

Guide bars typically last through the lifespan of approximately 4 chains with proper maintenance. Extend bar life by flipping it regularly to ensure even wear on both sides. Subsequently, remember to clean accumulated sawdust from oil holes and the bar groove periodically.

Common Causes of Chain Wear and Damage

External factors dramatically shorten chainsaw chain life, often necessitating premature replacement. Understanding these common culprits helps extend your chain’s service life and reduces maintenance costs.

Hitting rocks, nails, or metal

Contact with metal objects or rocks causes immediate and often irreparable damage to chainsaw chains. Upon hitting a nail or rock, sparks typically fly as teeth become severely damaged. Primarily, this type of impact damages individual teeth, often shortening or breaking them completely.

Even brief contact with metal objects will straightaway blunt your saw. In many cases, hitting embedded objects like barbed wire or nails makes the chain unusable, as it creates uneven teeth that cause increased vibration and dangerous “snatching” during cuts.

Cutting frozen or dirty wood

Frozen wood dulls chainsaw chains at an alarming rate – comparable to hitting rocks. Notably, cutting frozen material wears down the top of the tooth, making it appear “filed down” rather than showing edge damage. For that reason, cutting in winter often requires more frequent sharpening.

Dirt acts as a powerful abrasive against chain teeth. Even minimal contact with soil can significantly dull cutting edges. Above all, sawdust and dirt particles can also clog the oiler mechanism, preventing proper lubrication.

Lack of lubrication and overheating

Inadequate chain lubrication ranks as the leading contributor to premature chain wear. Without proper oil, the chain and bar quickly overheat, resulting in accelerated metal-on-metal damage.

When the oil reservoir empties or the oiler clogs, chainsaw components become increasingly hot, leading to potential failure. Regular application of quality bar oil reduces friction, minimizes heat buildup, and extends chain life considerably. Incorrect chain tension—either too tight or too loose—compounds these issues by increasing friction and strain on components.

Conclusion

Maintaining your chainsaw components represents a crucial aspect of both safety and cutting efficiency. Throughout this guide, we’ve examined the warning signs that tell you when replacement becomes necessary. Your chainsaw chain typically lasts about five years with proper care, but certain indicators like fine sawdust instead of chips, uneven cutting, or damaged teeth signal the need for immediate replacement.

Chain sprockets demand equal attention since their condition directly affects overall performance. Remember the 0.5mm wear depth guideline and consider replacing your sprocket after wearing through two chains. This practice prevents unnecessary strain on your equipment and maintains optimal power transfer.

Guide bars generally last through about four chains before requiring replacement. However, bent rails, insufficient groove depth, or visible damage call for earlier intervention. Flipping the bar regularly helps ensure even wear on both sides, therefore extending its useful life considerably.