The pitch on a chainsaw chain is the distance between three consecutive rivets divided by two. Chain pitch determines chain size and compatibility with the guide bar and sprocket. Common chainsaw chain pitches include 1/4 inch, .325 inch, 3/8 inch, and .404 inch.

What is Chainsaw Chain Pitch?

Chain pitch serves as the fundamental sizing measurement for every chainsaw chain. Essentially, it represents the distance between any three consecutive rivets divided by two. Think of pitch as the “spacing rule” that determines how far apart the chain’s main links are designed to sit.

Definition of chain pitch

The pitch of a chainsaw chain is measured in inches and typically expressed as a fraction (like 3/8″) or sometimes as a decimal (.404″). To calculate it yourself, locate any three consecutive rivets on your chain, measure from the center of the first to the center of the third, then divide that number by two. For example, if the distance between three rivets measures 3/4″, dividing by two gives you a 3/8″ pitch.

Why pitch matters in chainsaw performance

Chain pitch plays a crucial role in matching your chainsaw’s power with cutting efficiency. Different pitch sizes affect how the chain interacts with wood and how much power is required to operate effectively. The pitch measurement must match three components of your chainsaw system:

- The chain itself

- The drive sprocket

- The bar nose sprocket (if applicable)

Mismatched pitches can break sprockets, damage chains, and void warranties. Additionally, pitch influences cutting characteristics – larger pitches generally indicate heavier, bigger chains with different cutting properties. Professional users primarily choose 3/8″ pitch for its excellent balance of flexibility, weight, strength, and cutting speed on high-RPM professional saws.

Difference between pitch and gage

While often confused, pitch and gage are entirely different measurements:

Pitch refers to the spacing between chain links, while gage measures the thickness of the drive links that fit into the bar groove. Gage is typically .043″, .050″, .058″, or .063″ and determines whether the chain will fit properly in your bar’s groove.

Unlike pitch (which affects performance characteristics), gage primarily concerns the mechanical fit of your chain in the bar. Both measurements must match your chainsaw’s specifications precisely – however, getting pitch right affects how the entire system works together. If pitch doesn’t match the drive sprocket, the chain cannot sit properly on the sprocket teeth, resulting in rough operation, noise, and accelerated wear.

How to Measure Chainsaw Chain Pitch

Measuring the pitch of your chainsaw chain doesn’t need to be complicated. With the right technique, you’ll quickly determine this critical measurement to ensure proper fit and performance.

Step-by-step rivet method

The rivet method is the most reliable way to determine chain pitch directly from your chain. Here’s how to do it properly:

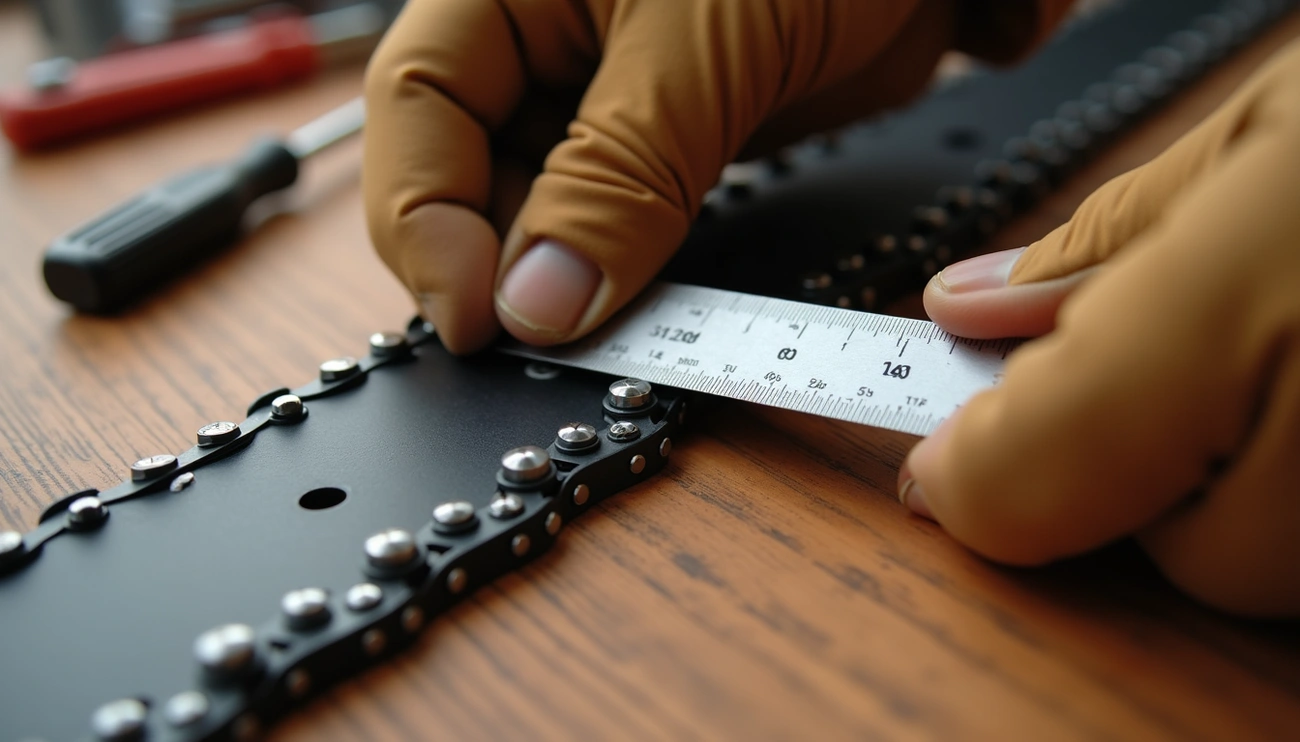

- Lay your chain flat on a stable surface

- Locate any three consecutive rivets (the small metal pins connecting the links)

- Measure from the center of the first rivet to the center of the third rivet

- Divide this measurement by two to calculate the pitch

For instance, if the distance between three consecutive rivets measures 3/4 inch, dividing by two gives you a pitch of 3/8 inch. This method works regardless of chain type or manufacturer.

Using stamped numbers on the chain

Many manufacturers stamp the pitch directly onto the drive links, saving you the trouble of manual measurement. Look carefully at the drive links for stamped numbers. On X-CUT chains, for example, the number “8” indicates a 3/8″ pitch. The pitch information may likewise appear on:

- The bar’s tail near the mounting location

- The rim of the spur on the chainsaw

- The drive sprocket or clutch drum

Tools you can use for accurate measurement

Beyond standard rulers, several specialized tools make pitch measurement more precise:

- Digital calipers provide exceptional accuracy when measuring between rivet centers

- Chainsaw gaging tools like Oregon’s Bar and Chain Measuring Tool or Granberg’s Pitch-N-Gage combine multiple measurement functions in one portable device

- Standard rulers work but require careful alignment with rivet centers

Common mistakes to avoid when measuring

Incorrect pitch measurement can cause serious problems. Avoid these common errors:

- Measuring between two rivets instead of three – this produces an incorrect result

- Confusing pitch with gage – remember pitch is about spacing, gage is about thickness

- Misinterpreting stamped numbers – verify what the numbers actually represent

- Not measuring from rivet centers – measurements must be from center points, not edges

Consequently, a chain with mismatched pitch may lead to binding, poor cutting performance, or even dangerous derailment during operation.

Matching Pitch with Other Chainsaw Parts

The perfect harmony among chainsaw components begins with matching pitch measurements across all parts. Think of your chainsaw as a synchronized system where each component must speak the same “pitch language” for optimal operation.

Why pitch must match bar and sprocket

Chain pitch must align perfectly with both your drive sprocket and guide bar nose sprocket. This three-way compatibility forms the foundation of safe and efficient cutting. Primarily, the pitch determines whether your chain will properly engage with the sprocket teeth. Unlike gage (which concerns thickness), pitch affects how the entire system works together. When all components share identical pitch measurements, power transfers smoothly from the motor through the sprocket to the chain.

How mismatched pitch can damage your chainsaw

Using incompatible pitch sizes creates a cascade of serious problems. Mismatched pitch between chain and sprockets will cause poor performance, excessive wear, and increased friction. Moreover, you risk:

- Binding and derailment – A chain with incorrect pitch won’t sit properly in the bar groove, creating dangerous operating conditions

- Accelerated wear on both the chain and sprocket

- Poor cutting efficiency due to improper engagement

- Potential system damage that could void warranties

Tips for checking compatibility before buying

Before purchasing replacement parts:

- Check your bar for stamped markings indicating recommended chain pitch

- Verify the sprocket pitch matches both bar and chain specifications

- Count drive links on your existing chain for accurate replacements

- Consider having a dealer measure your old chain if specifications aren’t clearly marked

Common Pitch Sizes and Their Uses

Chainsaw chain pitch varieties serve specific cutting needs, with each size offering distinct advantages depending on your application.

1/4″ – for small electric saws

The smallest pitch available creates an extremely narrow kerf, resulting in impressively clean cuts. Primarily found on top-handle pruning saws, pole saws, and carving saws, 1/4″ pitch chains cut like a “lightsaber” through smaller branches. Despite their precision, these chains require frequent sharpening and aren’t forgiving when pinched.

.325″ – for mid-range saws

This mid-sized pitch balances cutting speed with moderate vibration, making it ideal for 435/435e, 440/440e, 445/445e, and 450/450e models. Notably, .325″ chains feature industrial chrome-plated cutters that maintain sharper edges longer while reducing friction.

3/8″ – most common for pro users

The 3/8″ pitch dominates professional applications worldwide, typically fitted on 60-90cc saws. Indeed, this size offers the perfect balance of flexibility, weight, strength, and cutting speed on high-RPM professional saws. For smaller saws, 3/8″ low-profile chains are even more common, fitting guide bars 18″ or shorter.

.404″ – for heavy-duty cutting

Reserved for larger professional-grade saws, .404″ pitch excels in demanding timber operations. Often used by rescue workers and firefighters, this more aggressive cutting chain creates wider kerfs for faster chip clearance.

3/4″ – for industrial harvesters

The largest available pitch (.750″), 3/4″ chains are exclusively designed for mechanized harvesting equipment with burly, chipper-style cutters. These chains should never be installed on handheld chainsaws due to dangerous kickback potential.

Conclusion

Understanding chainsaw chain pitch stands as a fundamental aspect of chainsaw maintenance and operation. Throughout this guide, we’ve examined how pitch represents the distance between three consecutive rivets divided by two, essentially determining the spacing between chain links. This measurement directly impacts cutting performance, safety, and the longevity of your equipment.

Measuring your chain’s pitch accurately requires either the reliable rivet method or finding stamped markings on the chain itself. Additionally, specialized tools like digital calipers can help ensure precise measurements. Remember that an incorrect pitch measurement may lead to dangerous operating conditions, poor cutting performance, and premature wear of components.

Perhaps most importantly, your chainsaw functions as an integrated system where all components must share the same pitch specifications. Mismatched pitch between your chain, bar, and sprocket will certainly cause binding, excessive wear, and potential equipment failure. Always check compatibility before replacing any component of your chainsaw system.