A chainsaw chain can typically be sharpened 3 to 15 times before it needs replacement. The exact number depends on how much metal is removed during each sharpening and the overall wear on the chain. Heavily damaged or aggressively filed chains require replacement sooner.

How to tell when your chainsaw needs sharpening

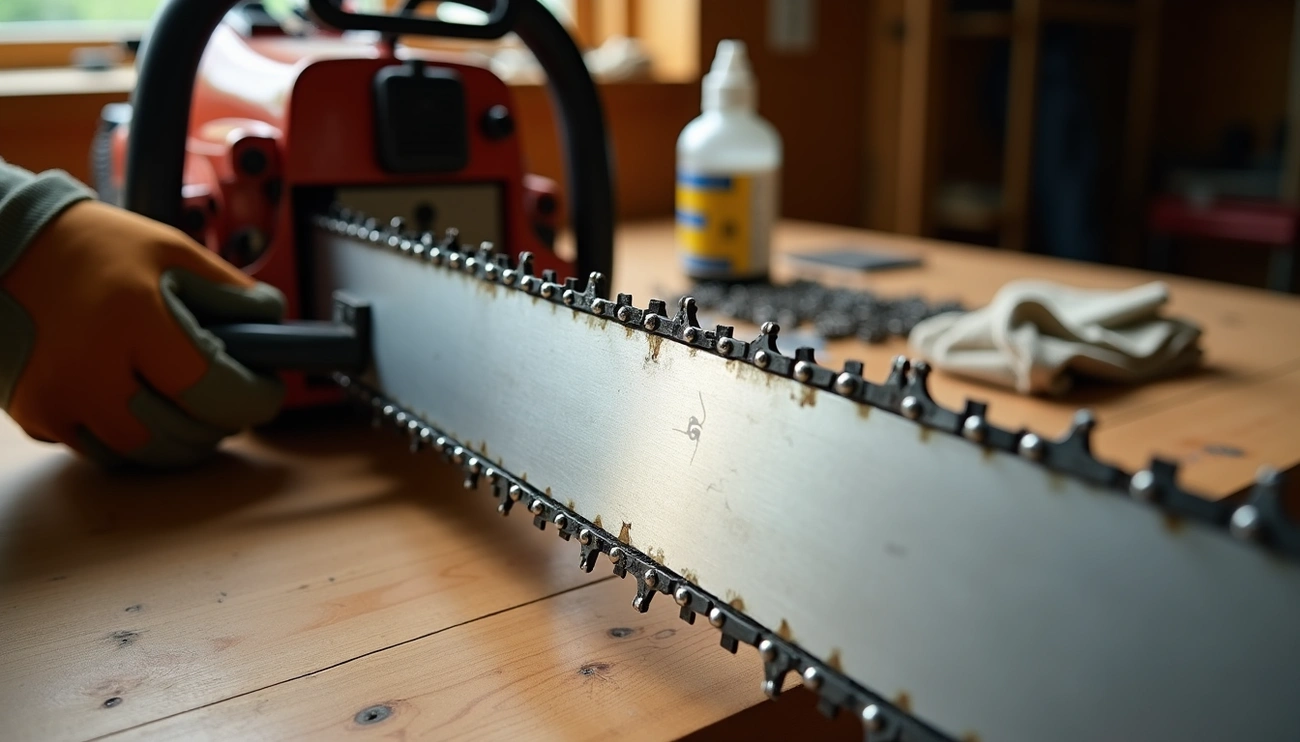

Keeping your chainsaw chain sharp is crucial for both safety and efficiency. A dull chainsaw not only makes cutting harder but also increases the risk of dangerous kickback. Understanding the signs of dulling and proper maintenance timing can significantly extend your chain’s life.

Signs of a dull chain

Recognizing when your chainsaw needs sharpening isn’t complicated if you know what to look for. Your chainsaw actually communicates its sharpness status through several clear indicators:

- Fine sawdust instead of wood chips – Perhaps the most obvious sign, a sharp chain produces large, uniform chips while a dull one creates fine sawdust or powder

- Increased cutting resistance – When your chainsaw no longer pulls itself into the wood and requires pressure to cut, it’s definitely time to sharpen

- Smoke despite proper lubrication – Smoke appearing during cutting (with correct chain tension and lubrication) indicates excessive friction from a dull chain[62]

- Uneven or crooked cuts – If your saw pulls to one side or produces uneven results, this often means uneven or dull teeth

- Unusual vibration – Excessive bouncing or vibration during operation makes precise positioning difficult

How often should I sharpen my chainsaw?

The sharpening frequency depends largely on usage conditions. Professional loggers often sharpen after each tank of fuel[72]. For regular users, here’s a practical guideline:

Every 3-5 hours of cutting clean softwood requires one sharpening, while hardwood may need sharpening after just 1-3 hours. Additionally, many experts recommend sharpening every time you refill your saw with gas and oil. This might seem excessive, but it’s actually easier to maintain a nearly sharp chain than to restore a very dull one.

What causes chains to dull quickly?

Several factors can accelerate chain dulling. Contact with dirt, rocks, or metal instantly damages cutting teeth and is one of the primary culprits. Moreover, cutting at too steep an angle puts unnecessary strain on the chain.

Certain wood types also affect sharpness – hardwoods like maple and hickory are particularly demanding on chains. Furthermore, dirty or embedded wood containing minerals near the stump can quickly dull even the sharpest chains.

Improper maintenance issues like incorrect raker depth or backward chain installation can also make your chain seem dull even when it’s not. By understanding these causes, you can take preventive measures to extend your chain’s sharpening life.

How many times can a chainsaw chain be sharpened?

The lifespan of a chainsaw chain isn’t measured in time but rather in the number of sharpenings it can withstand. Understanding these limits helps maximize your investment and maintain cutting efficiency throughout your chain’s service life.

Typical sharpening limits

Generally, you can sharpen a chainsaw chain between 3 and 10 times before replacement becomes necessary. For recreational users with proper maintenance, this number can reach 10-30 full sharpenings over a chain’s lifetime. Professional-grade chains maintained meticulously may endure 20-80+ sharpenings. Consequently, a research study found that 77% of discarded chains could have been sharpened at least once more, with an average of 4.54 additional possible sharpenings.

What affects the number of sharpenings?

Several key factors determine how many times your chain can be resharpened:

- Chain quality: Professional-grade chains typically withstand more sharpenings

- Materials cut: Hardwoods dull chains faster than softwoods

- Maintenance routine: Regular cleaning and proper tensioning extend chain life

- Sharpening technique: Each sharpening removes metal—aggressive filing shortens chain life

- Cutting conditions: Contact with dirt, rocks or metal can cause damage requiring immediate replacement

The amount of metal removed during each sharpening session primarily dictates longevity. Unless you hit obstacles, light touch-ups (removing minimal metal) substantially increase your chain’s useful life.

When to stop sharpening and replace the chain

Most manufacturers include wear markers on chainsaw teeth that indicate sharpening limits. Once these markers are reached, continuing to file past them significantly reduces cutting performance and increases the risk of teeth breaking off.

Furthermore, examine the bottom of each tooth—a wear marker exists above the “toe” and “heel.” If the chain runs without proper lubrication or with excessive tension, this area wears prematurely.

Other replacement indicators include:

- Chain stretching beyond tightening capacity

- Depth gages (rakers) becoming too low

- Tooth damage extending beyond the hardened surface

- Uneven teeth that cannot be restored to uniform length without excessive metal removal

Remember that optimal performance comes from replacing chains before they’re completely worn out—not after they’ve become dangerous.

Tools and methods for sharpening your chain

Proper tools make all the difference when maintaining your chainsaw chain. Sharpening equipment ranges from simple manual files to advanced electric systems, each with its own advantages depending on your needs and experience level.

Manual file guide

Manual filing remains the most accessible method for most chainsaw owners. This approach requires a round file matching your chain’s specifications, a file guide, and sometimes a flat file for depth gages. The file guide serves two crucial purposes: providing a flat surface for positioning the file on the chain and controlling filing depth. These guides typically cost around $10, with a two-pack of round files adding another $7.

To use a manual guide effectively, first secure your chainsaw in a vice. Then place the guide over the cutter with approximately 20% of the file positioned above the cutter’s top plate. Make steady, even strokes, maintaining consistent filing angles (usually 25-30°) throughout. Complete all cutters on one side before switching to the other side.

Electric sharpener

For those who sharpen chains frequently, electric sharpeners offer speed and precision. Benchtop models function similar to power miter saws but use grinding wheels instead of blades. These machines deliver professional-grade results by maintaining precise angles and consistent material removal across all teeth.

Portable electric options include battery-powered models that sharpen in the field. Many users report complete sharpening in 12-15 minutes with electric models compared to the 30+ minutes often needed for hand filing.

Rotary tool and grinder

Rotary tools like Dremel provide a middle ground between manual filing and dedicated electric sharpeners. These versatile tools accept sharpening attachments specifically designed for chainsaw maintenance. Most sharpening kits include multiple grinding stones (typically 4.0mm, 4.5mm, 4.8mm, and 5.6mm) to accommodate different chain sizes.

For optimal results, rotary tool sharpening should be performed at approximately 30° angle with slow, multiple strokes on each blade. The advantage here is speed—significantly faster than manual filing while maintaining good control.

Choosing the right file size

Selecting the correct file diameter is critical for proper tooth geometry. The chain pitch (distance between three consecutive rivets divided by two) determines the appropriate file size:

- 1/4″ pitch chains require 4.0mm (5/32″) files

- .325″ pitch needs 4.8mm (3/16″) files

- 3/8″ standard pitch uses 5.2mm (13/64″) or 5.5mm (7/32″) files

- 3/8″ low profile requires 4.0mm (5/32″) files

- .404″ pitch demands 5.5mm (7/32″) files

Thus, understanding your chain’s specifications ensures you’ll select the proper sharpening tools for maintaining optimal cutting performance throughout your chain’s usable life.

How to extend the life of your chainsaw chain

Extending your chainsaw’s cutting life requires proper maintenance. The right practices can dramatically increase your chain’s longevity, saving both time and money on replacements.

Proper storage and lubrication

Store your chainsaw in a dry, well-ventilated area away from direct sunlight and moisture. Before storage, always clean the chain thoroughly and apply a fresh coat of bar oil to prevent rusting. For long-term storage, consider removing the chain and storing it in a container of oil.

Proper lubrication is crucial – always use high-quality bar and chain oil, never waste motor oil. In summer, use SAE 30 or bar oil; in winter, switch to SAE 10. A properly functioning oiler should use a full tank of oil before emptying a tank of gas.

Avoiding contact with rocks and metal

Contact with dirt, rocks, or metal will instantly dull your chain. When cutting near ground level, always support logs sufficiently to avoid accidental contact with soil. Even brief contact with dirt can dull cutters immediately.

How long do chainsaw chains last?

With proper maintenance, standard chains typically last 30-50 hours of active cutting. Semi-chisel chains may extend to 40-60 hours, while sharper full-chisel chains generally last 25-40 hours. For occasional homeowners, a well-maintained chain can last 5+ years, whereas professionals might replace chains multiple times annually.

Conclusion

Proper chainsaw chain maintenance ultimately extends your tool’s life while ensuring safe and efficient operation. Throughout this guide, we’ve seen that most chains can be sharpened between 3-10 times, though well-maintained professional-grade chains might withstand up to 80 sharpenings.

Your chain actually communicates when it needs attention through telltale signs like fine sawdust production instead of chips, increased cutting resistance, and smoke during operation. Therefore, developing the habit of regular inspection saves both time and money in the long run.

Additionally, the sharpening method you choose significantly impacts your chain’s longevity. Whether you prefer the precision of manual filing, the speed of electric sharpeners, or the convenience of rotary tools, using the correct file size for your specific chain pitch remains essential.

Certainly, preventative care makes the biggest difference in how many sharpenings your chain can endure. Accordingly, proper storage in a dry place, consistent lubrication with quality oil, and careful cutting to avoid ground contact will dramatically extend your chain’s useful life.