Yes, you can put a bigger bar on your chainsaw if the engine has enough power to handle it. Most saws can increase bar length by 2 inches, such as from 16″ to 18″. Oversizing the bar can reduce cutting speed, strain the engine, cause oiling problems, and create safety risks.

Understanding Chainsaw Bar Compatibility

The compatibility between a chainsaw and its bar is determined by several crucial technical factors. To begin with, the physical mounting requirements must match perfectly—the bar’s shank must align with the saw’s mounting slot, studs, and tensioning mechanism.

What determines bar size limits?

The primary factors limiting bar size include the saw’s power output, oiling capacity, and mounting specifications. A chainsaw’s bar mounting system has specific dimensions that must match precisely, including the mounting slot, stud spacing, and tensioner reach. Moreover, the oil pump must deliver sufficient lubrication throughout the bar’s length. Small chainsaws with fixed oil pumps often struggle to adequately lubricate longer bars, leading to premature wear and potential safety issues.

The cutting length—the portion of bar extending from the saw body—is actually more important than the total bar length when evaluating compatibility. This useful measurement, combined with the chainsaw’s power rating, gives you a realistic picture of what your machine can handle.

Can I put a longer bar on my chainsaw?

While physically installing a longer bar is sometimes possible, doing so safely and effectively depends on multiple mechanical limits of your saw. Simply fitting a 20-inch bar on a 16-inch chainsaw isn’t just about whether it attaches properly.

Exceeding manufacturer recommendations typically leads to:

- Reduced chain speed under load

- Increased clutch and drivetrain wear

- Potential overheating

- Higher kickback risk

Manufacturers establish maximum bar lengths based on extensive testing. As one professional notes, “Each manufacturer will have a maximum bar length that can be used for each model”. Ignoring these specifications can not only damage your saw but also void your warranty and create safety hazards.

How engine size affects bar length

Engine power, measured in cubic centimeters (cc), directly determines what bar length your chainsaw can effectively handle. As a general guide:

- 36-45cc engines: suitable for 14-20″ bars

- 46-60cc engines: can handle 16-24″ bars

- 60-75cc engines: appropriate for 18-28″ bars

- 76-90cc engines: can manage 20-32″ bars

A small 40cc saw is typically limited to a 16″ or perhaps 20″ bar. Attempting to use longer bars on underpowered saws forces the engine to work harder, potentially causing it to bog down, overheat, or suffer accelerated wear.

Although some enthusiasts claim “you can never have too big of a saw”, practical experience shows that matching bar length to your specific cutting needs and chainsaw power offers the best results in terms of safety, efficiency, and equipment longevity.

Manufacturer Guidelines and Technical Limits

Manufacturer specifications exist for good reasons, particularly when it comes to chainsaw bar length limitations. Even if a larger bar physically fits your chainsaw, numerous technical factors determine whether this modification is safe or practical. Let’s examine these critical limitations in detail.

Why you should check your chainsaw manual

Your chainsaw’s operation manual is the definitive resource for determining compatible bar lengths. As one expert emphasizes, “Always refer to the manufacturer’s recommendations” to avoid potential damage to your equipment. The manual typically specifies:

- Maximum and minimum bar lengths appropriate for your model

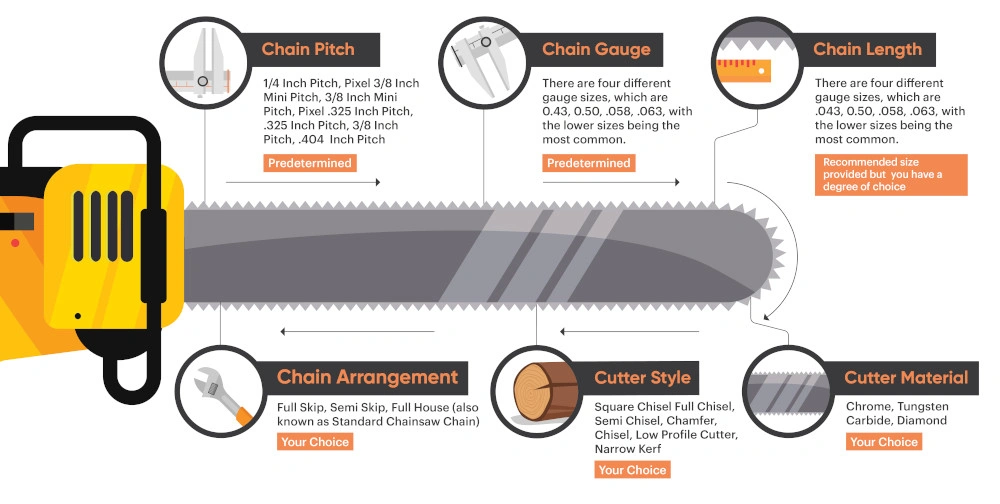

- Compatible chain specifications (pitch and gage)

- Required maintenance procedures for different bar lengths

Furthermore, many manufacturers explicitly state that damage resulting from using inappropriately sized bars isn’t covered under warranty. As Cannon Bars notes, they are “not liable for saws damaged as a result of using inappropriately long or short bars”.

Oiling system and chain tensioner limitations

Even when a longer bar physically fits, your saw’s oiling system might be inadequate for the increased length. Longer bars demand greater oil flow, and fixed oil pumps on smaller saws often cannot deliver sufficient lubrication throughout an extended bar. Consequently, this leads to:

- Increased friction and heat

- Premature chain and bar wear

- Higher risk of chain derailment or breakage

Similarly, tensioner limitations present another obstacle. Your saw’s tensioner must have sufficient travel to tighten a longer chain properly. A chainsaw owner described this issue: “When I run the chainsaw after properly tensioning the chain, the chain appears to be tightening and becomes very hot”.

Can I put a 20 inch bar on a 16 inch chainsaw?

In most cases, replacing a 16″ bar with a 20″ bar is ill-advised unless specifically permitted by the manufacturer. Key considerations include:

- Bar shank compatibility – The mounting dimensions must match exactly

- Oiling capacity – Smaller saws typically have insufficient oil flow for longer bars

- Power requirements – A 16″ saw usually lacks the necessary power for a 20″ bar

Despite the technical possibility in some instances, users should expect “reduced performance and accelerated wear” with such modifications. If you frequently need a longer bar, purchasing a saw designed for that purpose represents a safer, more efficient solution.

Risks of Using a Bar That’s Too Long

Installing an oversized bar on your chainsaw creates several risks that can affect both performance and safety. Understanding these potential problems will help you make informed decisions about chainsaw modifications.

Reduced cutting performance

Fitting a bar that’s too long for your chainsaw’s power rating typically results in sluggish cutting. The chain speed decreases under load, causing the saw to bog down during cuts. Subsequently, this reduced power leads to slower work completion and potentially incomplete cuts when tackling larger trees.

Increased wear and tear on the engine

Oversized bars place excessive strain on your chainsaw’s engine. The motor must work harder to maintain chain speed, often operating near maximum capacity. This constant strain shortens component life and can lead to premature engine failure. Clutches particularly suffer from this added stress.

Safety hazards and kickback risks

Perhaps most concerning, longer bars significantly increase kickback danger. The extended bar tip creates a larger kickback zone, making the saw harder to control. In contrast to properly sized equipment, oversized bars make chainsaws unwieldy and dangerous, especially for less experienced operators.

Impact on fuel efficiency and vibration

Fuel consumption rises dramatically with oversized bars as engines struggle to maintain power. Additionally, the imbalance created by a too-long bar increases harmful vibration. Ultimately, these vibrations can cause operator fatigue and long-term health issues like Hand-Arm Vibration Syndrome (HAVS).

When and How to Upgrade Safely

Deciding when to upgrade your chainsaw bar requires careful evaluation of your cutting needs. Proper matching of equipment to task ensures both safety and efficiency.

Signs you need a long bar chainsaw

If you regularly cut trees 20-30 inches in diameter or engage in timber harvesting, a longer bar might be necessary. For milling applications, your capacity is directly determined by your bar size. Yet, many experienced cutters find that for general use, a 16-18″ bar offers optimal balance between power and maneuverability.

Choosing the right bar and chain combo

For optimal results, match your chainsaw’s engine power with appropriate bar length. Take your log diameter and add six inches to determine your minimum bar length. For milling specifically, consider these guidelines:

- Up to 18″ logs: Use 55-67cc engines

- 18″ to 36″ logs: Use 68-85cc engines

- 36″ and larger: Use 86-120cc engines

Can you put a bigger bar and chain on a chainsaw?

While physically possible in some cases, safely upgrading depends entirely on your saw’s power capacity. A general rule suggests taking your saw’s cc rating and dividing by two for maximum bar length in inches. Additionally, using specialty ripping chains helps reduce strain when milling with longer bars.

Best practices for chainsaw milling

For efficient milling, use proper equipment like an Alaskan mill, guide rails, and wedges. Refill both gas and bar oil after each cut. Essential safety gear includes respirator, hearing protection, and face shield. For easier cutting of larger logs, prop one end up to create a downward angle.

Alternatives: hiring a portable sawmill

For occasional projects, hiring a portable sawmill service (approximately $45/hour) often provides better value. This approach yields more lumber per hour than chainsaw milling and eliminates the need for specialized equipment investments. Consider this option especially for one-time or infrequent milling needs.

Conclusion

Ultimately, while you can physically mount a bigger bar on some chainsaws, doing so requires careful consideration of multiple factors. Throughout this article, we’ve seen that your chainsaw’s engine power, oiling capacity, and tensioning system all play crucial roles in determining compatible bar lengths.

Exceeding manufacturer recommendations certainly comes with significant risks. Your chainsaw will likely experience reduced cutting performance, accelerated wear and tear, increased fuel consumption, and most importantly, heightened safety hazards including dangerous kickback. Therefore, always consult your owner’s manual before attempting any modifications to your equipment.

For those who genuinely need larger cutting capacity, purchasing a saw designed for longer bars represents a much better solution than forcing an underpowered machine to handle oversized components. Additionally, for specific tasks like milling large logs, hiring a portable sawmill service might prove more efficient and cost-effective than investing in specialized equipment you’ll rarely use.