Replace a chainsaw bar if it’s bent or twisted, the groove is badly worn, the edges are flared, or the nose sprocket is damaged. Excessive chain wobble or a large lip also means it’s worn out. With proper oiling, most bars last about four chains.

How to tell if your chainsaw bar is worn out

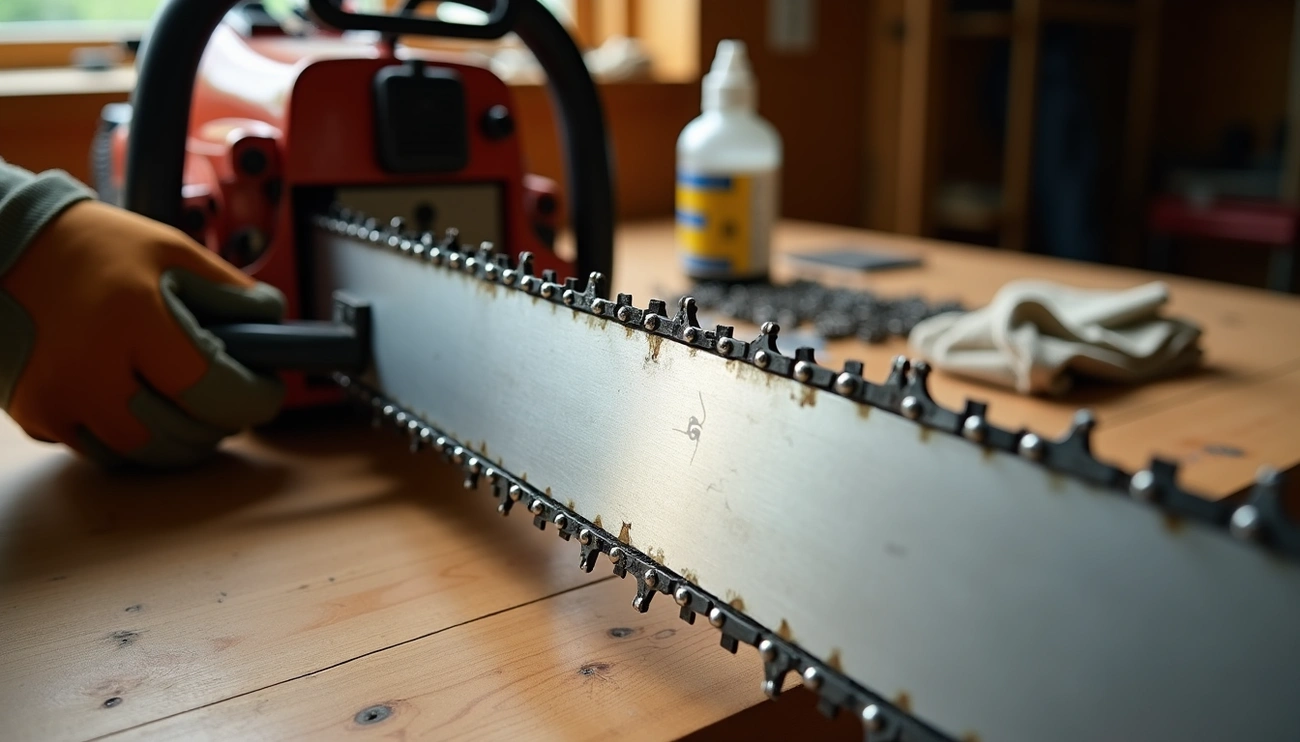

Properly maintaining your chainsaw requires regular inspection of the guide bar. Recognizing bar wear early can prevent costly repairs and dangerous operating conditions. Let’s examine the most reliable methods to determine whether your chainsaw bar needs replacement.

1. Check for rail wear and groove depth

The most critical indicator of chainsaw bar condition is the depth of the bar groove. As chains rotate around the bar at high speeds—approximately 80 feet per second—they gradually wear down the bar rails. To check rail wear, place a straightedge against the bar and the cutting edge of one cutter, then force the cutter sideways. A properly functioning bar should show a 1/16 to 1/8-inch gap between the straightedge and the bar body.

Furthermore, measure the groove depth in the area where most cutting occurs—typically the underside of the bar. For solid nose bars, measure where the heaviest cutting happens; for sprocket nose bars, measure at the nose. If depth falls below minimum specifications (generally 5/16″ minimum), it’s time for replacement.

2. Look for uneven or slanted cuts

Crooked cutting is a telltale sign of bar problems. Your chainsaw might pull to one side because the guide bar rails have become asymmetrical—one rail lower or thinner than the other. Additionally, this can create a dangerous cycle: uneven bar wear causes the chain to rotate at an angle rather than aligned with the bar, subsequently creating more uneven wear.

Most importantly, if you notice your chainsaw consistently cutting in a slanted pattern despite proper chain sharpening, inspect your bar immediately. This usually indicates significant bar rail damage that likely necessitates replacement.

3. Inspect for burrs or sharp edges on the bar

Throughout normal operation, wire-like edges called burrs often form on the outside of bar rails. These sharp edges not only create drag in cuts but can eventually break off and take good rail material with them. Using a fine-tooth flat file, carefully remove these burrs before they cause further damage.

Inspect your bar regularly for these burrs, particularly after heavy cutting sessions. The presence of significant burring indicates accelerated wear and may signal the need for closer examination of your bar’s overall condition.

By conducting these three inspections routinely, you’ll maximize your chainsaw bar’s lifespan and maintain optimal cutting performance.

Common chainsaw bar problems and what they mean

Recognizing the symptoms of chainsaw bar problems helps determine exactly when to replace a chainsaw bar. These warning signs often appear gradually, nevertheless, addressing them promptly can prevent serious damage to your equipment and ensure safe operation.

1. Chain not moving smoothly

A chain that’s difficult to rotate by hand typically indicates bar groove issues. This problem often stems from debris clogging the bar track, although it may also result from pinched sections in the bar channel. First, clean out the bar groove thoroughly with a screwdriver narrow enough to reach the bottom. Moreover, check the guide bar sprocket—it should turn freely. If the sprocket doesn’t turn or the chain remains difficult to move after cleaning, your bar likely needs replacement.

2. Excessive vibration during use

Abnormal vibration creates more than just discomfort—it potentially leads to serious hand-arm injuries and premature equipment failure. Vibration typically occurs due to uneven cutter teeth sharpening or depth gages cut at inconsistent heights. In fact, even minor differences in cutter tooth length or sharpening angles can cause significant vibration. Additionally, worn isolators or springs in your chainsaw’s anti-vibration system might need inspection and replacement.

3. Chain jumping off the bar

Whenever your chain repeatedly derails, inspect the bar track for damage. The groove width should measure only .002″ to .005″ wider than your chain gage. As the bar wears, this gap increases, allowing the chain to tilt and eventually jump off. Likewise, a damaged bar with uneven rails contributes to this dangerous problem. Immediately replace bars with visible cracks, significant rail damage, or extreme wear.

4. Burn marks or discoloration

Blue or black discoloration along the bar indicates dangerous overheating from inadequate lubrication. These burn marks often appear first at high-friction points, especially on the bottom edge where cutting occurs most frequently. At this stage, the bar’s hardened surface has likely worn away, henceforth accelerating deterioration.

5. Chain tension issues

Proper tension is crucial—too loose increases kickback risk and derailment; too tight damages components through overheating. Always tension the chain while it’s cool, never hot. You’ll know tension is correct when the chain feels snug yet pulls freely around the bar and snaps back into position after being pulled down and released.

When to replace vs. when to repair your bar

Deciding between repairing or replacing your chainsaw bar depends on several specific factors. Unlike chains that require frequent replacement, bars typically last through about four chain lifespans if properly maintained.

1. Bent chainsaw bar: repairable or not?

Upon discovering a bend, remove the bar and examine it closely. Hold it level with your eye and look down the rails as if sighting a rifle—even slight bends become visible from this perspective. Minor bends can often be straightened by gently working them in the opposite direction. Consequently, if the bend is abrupt or the rails are cracked, replacement is your only option.

2. Cracks or chips in the bar

Inspect your bar rails carefully for cracks or chips, as these weaken structural integrity. Professional repair services typically charge around $210 for bar repairs—approximately half the cost of a new bar. Indeed, if repair costs approach 50% of replacement value, buying new is usually more economical.

3. Worn out bar nose or sprocket tip

Sprocket nose tips often wear out faster than the bar itself. Fortunately, many are replaceable without special tools. This simple replacement can restore functionality without purchasing an entire new bar, saving considerable money.

4. How to measure groove depth accurately

Measure groove depth where cutting pressure is greatest—typically the bottom edge. The minimum acceptable groove depth varies by chain type (approximately 4mm for 1/4P chains). Once depth falls below manufacturer specifications, replacement becomes necessary.

How to extend the life of your chainsaw bar

Proactive maintenance dramatically extends your chainsaw bar’s lifespan, helping you avoid premature replacement costs. These six essential practices will maximize performance throughout its service life.

1. Flip the bar regularly

Rotating your bar every 8-10 hours of cutting or after 2-3 uses ensures even wear on both sides. First of all, this simple habit prevents one-sided rail wear that causes crooked cutting. To flip correctly, remove the bar, clean it thoroughly, rotate it 180 degrees, then reinstall.

2. Keep the bar and chain well-oiled

Fill your chainsaw’s oil reservoir each time you refuel. As a result, proper lubrication reduces friction and heat that accelerate bar wear. Use only dedicated bar and chain oil with high tackiness – never substitute with motor oil, which contains metal particles that damage rails.

3. Use proper chain tension

Correct tension is crucial – too loose damages rails, too tight overheats components. Above all, check tension before starting work and periodically during operation. The chain should sit snugly against the bar yet move freely when pulled.

4. Clean the bar track frequently

After each use, remove debris from the bar groove using a scraper or narrow screwdriver. Simultaneously, clear oil holes to maintain proper lubrication flow. This prevents hardened sap and sawdust from restricting chain movement.

5. Match the chain and bar correctly

Your chain must match the bar’s length, gage, and pitch specifications. Incompatible components accelerate wear and create safety hazards.

6. Store your chainsaw properly

Before storage, clean the bar thoroughly and apply a light coating of oil to prevent rust. Store in a dry area away from humidity, ideally with a protective bar cover.

Conclusion

Proper chainsaw bar maintenance saves both money and frustration in the long run. After all, replacing a bar costs significantly more than taking steps to extend its life. Through regular inspection of rail wear, groove depth, and cutting performance, you’ll spot problems early and prevent dangerous operating conditions.

Remember that a quality chainsaw bar should last through about four chain lifespans. Accordingly, if you’re replacing bars more frequently, something isn’t right with your maintenance routine. Simple habits like flipping the bar regularly, keeping proper chain tension, and ensuring adequate lubrication can easily double your bar’s useful life.

The decision between repair and replacement becomes clearer once you understand the warning signs. Though bent bars, worn grooves, and damaged rails might seem like minor issues at first, they quickly affect cutting performance and safety. Most importantly, addressing these problems promptly prevents the kind of damage that necessitates complete replacement.